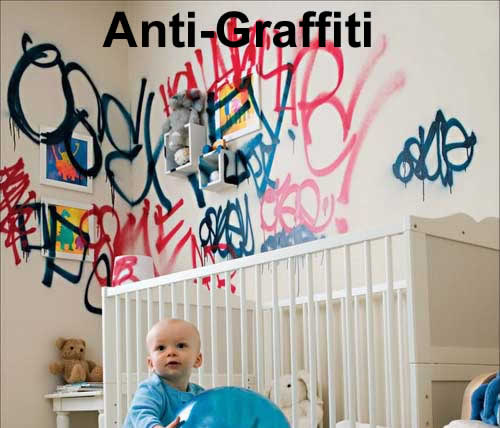

Anti-Graffiti Coating

Quick Overview

Anti-Graffiti coating represents a new class of tough thin and durable advanced polymers. This easy to apply coating turns ordinary walls and ceilings into a cleanable canvas of art. It’s unique physical properties give it superior cleanability and resistance to Sharpie solvent markers and most paints. Universal rubbing alcohol is used as the cleaner fluid with a dry clean rag. The Anti-Graffiti Coating is used on school room walls to replace blackboards and dry erase boards, subway walls and ceilings to provide easier paint removal, hospital walls and floors to enable easy clean up sanitary surfaces, protect outdoor building walls, steel and concrete bridges members, public bathroom walls and any surface indoor or out which requires graffiti protection or to aid in cleaning.

This 70% solids 2-component coating is water based and therefore is easy to clean up using soap and water. It is easily applied using roller, air-less spray machine or brush. Pot life after mixing is 30 minutes with air dry tack free surface time of 45 minutes depending on ambient humidity. It may be formulated in just about any color or clear as its natural state. It exhibits a high functioning temperature of 220°F, excellent abrasion and outdoor UV stability. It remains flexible at 0°F and can withstand light mild solvent attack. Given this materials extraordinary clean-ability and durability characteristics it lends itself to many diverse demanding applications.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

Technical Application Data

Anti-Grafitti is a two component 70% solids aliphatic high performance coating. It has very low odor. Application temperature ranges from 60°F to 100°F. This material should not be applied to hot surfaces above 110°F. Working time at 75°F is approximately 1 hour. *For use as a primer to achieve superior adhesion to substrate, mix A & B components 1A:1B ratio. For smooth self-leveling topcoats, use a mix ratio of 1A:2B. When used with color, use 1A:3B ratio. Always stir the B-Side thoroughly with jiffy mixer at low rpm prior to use while not inducing air (prevent entrapment of micro air bubbles). Functional operation temperature ranges from -40°F to 200°F. Anti-Grafitti is designed as a “Thin-Mil” coating and is not to be applied in thicknesses greater than 6-8 mils at one time. Coverage is approximately 250 sq. ft./ mixed gal.

Physical Properties

| Anti-Graffiti Physical Properties | ||

|---|---|---|

| Optical Clearity | Visual | Clear |

| Tensile Strength | ASTM D412 | 3410 psi |

| Elongation | ASTM D2256 | 350% |

| Hardness -Shore D | ASTM D785 | 45D |

| Abrasion -TaberCS17 | ASTM D4060 | 60 mg/1k cycles |

| Gel Time | Time | 45 min |

| Mix Ratio | PBV | 1:2 |

Adhesion Results

Adhesion Results of Typical Substrates per ASTM D-4541 Elcometer

| Concrete- Primed | >50 psi | Excellent bonding |

| Steel- Primed | >50 psi | Excellent bonding |

| Wood- Primed | >50 psi | Excellent bonding |

Substrate Surface Preparation

Preparation of substrate surface prior to the application is extremely important as durability is only as good as the weakest link in the coating system.

Concrete must be fully cured and should be prepared with a sandblasting, diamond grinding or machine sanding depending on the severity of the concrete surface condition. Similar proper preparation must be performed for metals. Primers also require this proper preparation. Always power clean using mild detergent prior to sanding, etc. Call Tech Support Group for assistance with selecting SSS application system. Also read the Application Page on this website. If patching concrete, use our mineral filled fast-set Acrylic Modified Epoxy applied by trowel. For expansion joints, use Joist Seal applied by hand cartridge dispensing gun. It is always best to perform a test within a small section of the application area prior to full scale engagement.

Allow Anti-Graffiti coating to cure for 5 days.

This technical data information is accurate to the best of our knowledge. SuperSkinSystems™ Inc. makes no warranty, expressed or implied within the materials on this website, its use or with its any application. SuperSkinSystems™ Inc. shall not be liable for material or application related injuries, material non-conformance, application failures or any consequential damage by the use of this product.

Reviews

There are no reviews yet.