-

ClearSkin

Clearskin is a 100% solid aliphatic roll on coating. There are two versions available as roll on.

- 12-15 minute pot life and set to touch in 30 minutes.

- 1 hour pot life and 45 minutes set to touch.

Both produce a clear hard high gloss coating. Both 1&2 can be supplied in colors and both have excellent chemical and UV resistance. #1 has been found to have excellent electrical properties. 16 mils of coating can resist 10000 volts. Making it a great insulator.

Clearskin makes an excellent coating for steel, concrete, wood and marine applications. Its ability to cure fast with no VOCs reduces downtime to return to service. Clearskin has excellent water and chemical resistance to meet any condition. Clearskin is optically clear but can be pigmented and can have anti-corrosive additives if needed.

-

Continuous Panel Laminator

SuperSkinSystems has developed a continuous foam panel laminating machine to produce foam boards for a variety of applications. This machine technology combined our foam chemistry technology may accommodate board stock widths as wide as desired utilizing multiple dispensing heads and increased conveyor units heads continuous 30″ wide board stock which may incorporate a host of outer skin materials and inner reinforcement materials sandwiched together using our RigidBuildingFoams or FireSkinFoams. These matrix foaming core materials may also be Bio-based and available in densities ranging from 2-30 pcf. The outer skins of the continuous panel may include a wide range of materials such as cardboard, wood, plastics, canvas, fabrics, metals and woven reinforcement cloths. Inner laminate materials such as Basalt, S-glass, Carbon or Kevlar fibers may also be incorporated into the panel to be used as structural reinforcements. Panels lengths may be cut to any size and widths may be narrowed down to just a few inches for specialized applications. Panels thickness may range from 0.25-4.0 inches.

Click here to view full model Decorative Panels may be achieved by color top-coating and sequential color texturing. Panels may be secondary coated with any SuperSkinSystems materials for desired specifications. Structural Panels used in flooring applications may be coated with our Non-Skid system or coated with our high dielectric coating to arrest electrical conduction. These lightweight very high strength panels utilize non-hydroscopic foaming cores to allow for exterior use. Typical panel uses include floors, walls, ceilings, roofs, exterior signage, decorative interior design, displays, furniture, structural reinforcing spars, boat transoms, firewalls, shielding, etc.

Given the diversity of materials which may be integrated into this Panel Composite and/or the selection of applied high-performance exterior coatings, these panels offer extraordinary characteristics which lends themselves into many diverse and demanding applications. For assistance in the selection of a panel construction and its application, please call or email our Technical Support Group.

-

Cushion Foam

Cushion Foam is a superior bio-based flexible microcellular open-cell foam designed to deliver very high toughness and durability for diverse fields of application such as furniture seating cushions, automotive seating, house-wraps, play toys, shock and vibration absorption, impact sports padding, sound-proofing, etc. Seating densities normally range from 3-5 pcf. Density formulations may be adjusted to accommodate other very specific requirements including colors.

This unique bio-based high resilient (HR) flexible foam exhibits very low compression set while providing dimensional stability through its wide operating temperature range. Cushion Foam is formulated from special MDI pre-polymers to create very fast production and de-molding cycles.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

Decorative TextureCoat™

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.

Decorative TextureCoat™ (DTC) is a tough weather resistant UV stable protective coating. It presents a decorative stucco-like texture finish which exhibits excellent durability and resistance to high wind abrasion, chemicals, staining and sunlight. This coating demonstrates a combination of many unique characteristics exhibiting excellent adhesion and penetrating capabilities securing a high performance bond to substrate. Decorative color texturing chips give this single component sprayable material a wide range of styling effects. This waterproofing exterior tough-coat may be used over diverse types of substrates such as existing stucco, concrete, brick, stone, metal, wood and composites.DTC is used as a waterproofing exterior topcoat sealer. DTC spray coating maintains good flexibility in severe hot and cold environments. It’s surface skin may be ultra-fine to medium to coarse. It is commonly used for face-lifting stucco and painted surfaces. It may also be mixed with other aggregates such aluminium oxide, walnut shells or fine stone creating anti-skid and finely styled decorative surfaces. See color textures chart for standard color blends.

Decorative TextureCoat™ is a high performance aliphatic coating with very low ordor during application. Color pigments and textures may also be added as desired. This material may also be applied directly to urethane foam materials in such applications as exterior artwork, architectural moldings or decorative facial panels.

-

EpoxyInjection

EpoxyInjection is a 2-component, 100% solids, toughened low-viscosity epoxy injection formulation specifically designed for in-place resin injection for cracked concreted structures such as dams, locks, canals, power plants, water reservoirs, water treatment facilities, foundations, parking garages, aqueducts, etc. This low viscosity epoxy is pumped into holes and cracks to create waterstops in weakened concrete infrastructure systems. It provides excellent adhesive characteristics while exhibiting good chemical resistance, water infiltration and exfiltration resistance. It exhibits low odor emissions, 0% VOCs, long working time, excellent cure at low temperatures and high humidities, superior hardness and low viscosity for high-penetrating injection. This material will bond to concretes, masonary and metals.

Epoxy Injection may be applied using plural component mixing pumping systems or conventional pressure pot/mix systems at a 2:1 dispensing ratio. This 2K epoxy injection material adds strength or structrual preservation to the concrete system when fully cured. Its cure times may be adjusted for specific difficult applications. It conforms to ASTM C-881, Types I, II, IV adhesive, Grade-1, Class C and AASHTO M-235 specifications.

Please contact our technical support group for specific substrate application procedures, equipment, safety gear and clean-up kits. Refer to MSDS for material and safety standard procedures.

-

FireSkin 1K

FireSkin™ 1K is a high temperature waterborne intumescent fire-resistant barrier coating that will withstand direct flame contact. It does not emit continuous smoke with E84 testing yielding 5=flame spread and 70=smoke during flame exposure. It is environmentally friendly and is used in demanding fire shielding applications such as mine safety, protecting steel frameworks, building foam insulation, utility poles, cedar shake roofs, styrene and polyurethane foam board and other flammable material protection. Designers also use this material’s unique decorative coating properties to enhance interior walls specified by fire-retardant requirements as acrylic texture chips may be added. 1K FireSkin also provides outstanding UV stability.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

It is a water-based formulation that is applied by low pressure air-less spray equipment, roller or brush. It is non-toxic and and may be appled in low-ventilated enclosed areas. Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.GlowSkin is capable of being added to Fireskin 1K.

-

FireSkin™ 2K

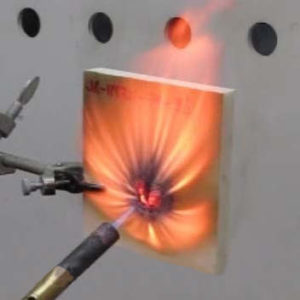

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.

FireSkin 2K super-polymer is an insulating microcellular polymeric material that will withstand direct flame contact. It emits low smoke and flame spread during flame exposure making it a valuable resource for diverse fire protection enclosure applications.It has been specially designed to coat polyurethane and polystyrene foams for fire protection. Other uses include protecting buildings, humans, animals and all nature against the destructive force of fire. Uses include deployable fire barrier systems, mobile structures, hazardous containers and specialily shielding systems for schools and apartments.

Please call or email our Technical Support Group for any questions regarding material, application or prospective uses.

-

FireSkin™ Foam

FireSkin Foam is an insulating material designed to withstand direct flame contact. It produces very low smoke and flame spread. The material develops an intumescent fire barrier which provides a protective shield against constant flame and extreme heat conduction to interior surfaces. These closed cell foams range in varing densities from 0.5-50 pcf for use in diverse fire protection system applications. FireSkin Foam is formulated as a Halogen-free, Class 1 fire rated foam containing renewable resource “Green” materials.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here.

FireSkin Foam delivers toughness and dimensional stability from -20F (-29C) to 250 F (130C). It is used in a variety of construction applications such as in roof, wall and floor building insulation and structural sandwich panel construction foam core materials. These materials have been designed to accommodate HFC 245 or Pentane blowing agent for maximum R-values. This material has been designed for use in economical Continous Panel Laminator machines as shown below. See LAB FIRE VIDEO1 here. See LAB FIRE VIDEO2 here. -

FireSkin™ Foam 0.5

Fireskin Foam 0.5 is a two component, 1-1 parts by volume, light density, spray applied polyurethane foam. To produce Fireskin Foam 0.5 requires the use of an A-Component (ISO) and a B-Component (RESIN), which contains zero ozone depleting blowing agents, catalyst, polyols and flame-retardant materials such as fiberglass, cellulose or other loose fill products. Typical areas where spray polyurethane foam is applied are interior walls, attics, ceilings and spa insulations.

-

GlowSkin

GlowSkin is a durable long-lasting glow-in-the-dark harsh environment coating used primarily in safety applications providing dark dangerous areas a strong nite-light. When fully charged by the sun or auxiliary lights, the nite-light GlowSkin lasts brilliantly for 2 hours. This material is embodied ClearSkin which delivers an extremely tough weather resistant coating. It exhibits excellent durability regarding resistance to abrasion, chemicals and sunlight. Being very tough, it is used primarily in exterior high-wear environments where severe topcoat protection is required. Although GlowSkin may be used directly on many types of surfaces, it is normally used over a reflective base-coat color such as white, yellow or silver to add more to the reflective-glow. GlowSkin top-coat is available in Green and Blue. Mixing together gives a gentle aqua or light teal.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.

GlowSkin is a very intense high-performance glow material used in military ships, transportation subways and tunnels, amusement parks, parking decks, office building stairwells, boat docks and the art world. It provides excellent adhesive characteristics and can withstand arctic freezing or desert hot conditions.Please contact our Customer Service and Technical Support Group for any questions or to provide direction with specific selection of a material system, questionable target surfaces, operational procedures, material pumping/spray machines, spray/pour guns, safety protection gear and clean-up kits. Please refer to MSDS for material safety information.